Tank management

Tanks are filled with beer from vessels by means of a hose or intake pipeline. Tanks are cooled to a temperature of 8-10°C whereby they may have an independent cooling system or they are kept in a cooled room. When being stored, beer retains its premium quality which is provided – among other things – by an exchangeable polypropylene plastic bag. Beer tapping is facilitated by pressurized air generated by an air compressor with filters.

Benefits:

- Beer does not come into contact with air, and its maximum quality is retained

- Possibility to draught non-pasteurized beer, i.e. a 100% natural product

- Tedious keg handling is eliminated

- Easy operation and maintenance

- Large-scale of draught beer facilitates retaining its favourable prices

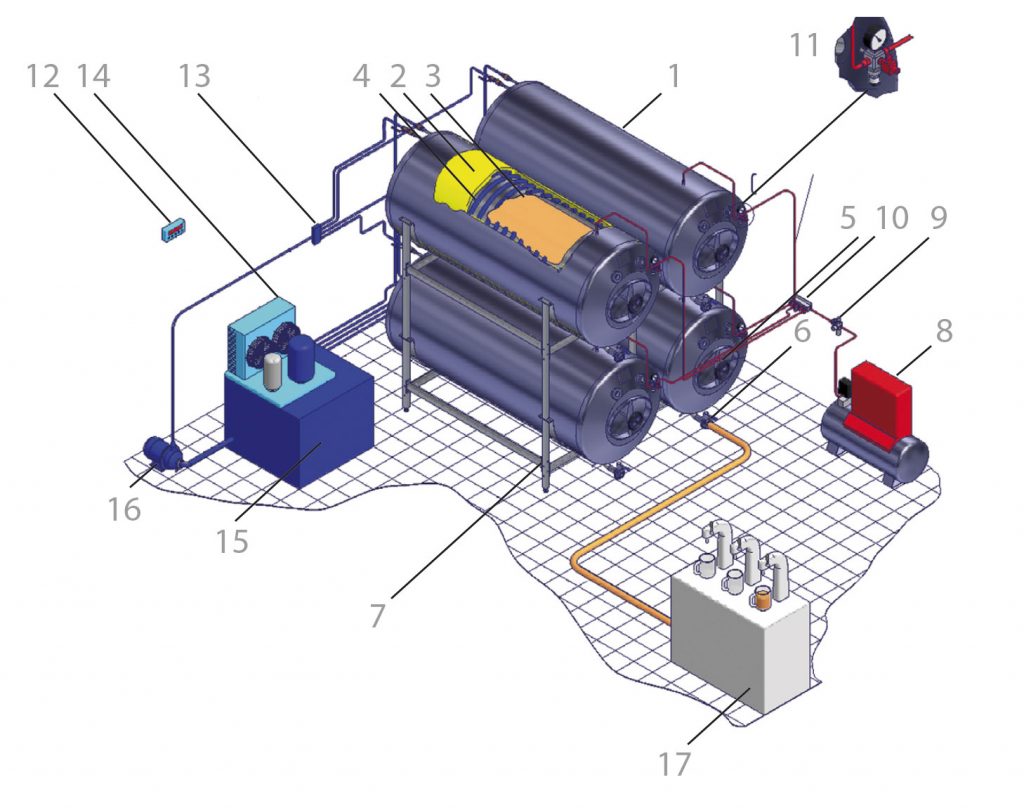

Tapping beer tanks WITH cooling

Beer

Compressed air

Coolant

Compressed air

Coolant

- Insulated beer tank 10 HL

- Polyurethane insulation 50 mm

- Cooling coil

- Inner lining

- Tank lid

- Valve

- Variable stands

- Air compressor

- Air treatment

- Air distributor

- Safety valve and manometer

- Electronic temperature control

- Cooling water distributor

- Cooling unit

- Coolant container

- Pump

- Draught beer dispenser