Verweise

The PSS SFV Speed Filler Vacuum is a multifunctional device designed for small, medium and large operations in the food industry. It gives perfect filling of meat products and other food products.

The device guarantees effective usage and ensures a continual process of metering and filling of processed materials. The processed material is fed into the hopper, where it is caught by two feeding worms that gently move it towards the metering device or to direct filling through the tube to the clipping machine.

The PSS SFV 720 can also be used with the ad-ditional grinding attachment, which ensures quality final grinding and subsequent material filling into appropriate casings. The PSS SFV is as standard equipped with a vacuum system, which inhibits the possible creation of air bubbles in the final product.

SFV 701

- speed filler vacuum (salami, sausages)

- for meat with a temperature from +3 °C to +50 °C

- without mixing spiral

SFV 705

- speed filler vacuum (salami, sausages, frankfurters)

- for meat with a temperature from +3 °C to +50 °C

- without mixing spiral

SFV 720

- speed filler vacuum (salami, sausages, frankfurters)

- for meat with a temperature from -4 °C to +50 °C

- with mixing spiral

The advantages of vacuum fillers

- Performance

- Multifunctionality

- Ideal handling of raw material

- Resistance

- Unique design

- Improved ergonomics

- Shorter tube of worms and shorter worms

- Front support of the worms (this increases the use time by 1.5 to 2 times)

- Maximal adaptation to technology of sausage production

- Very stable machine

- Easy cleaning of the underneath area is ensured by the solid base and height

- Adjustable feet

- Obtaining final product of excellent quality and ideal structure

- Lifetime of the main drive with the possibility of operating 24 hours a day without interruption

Applications for Speed Fillers

Dosing device

Dosing device of pulse type for frankfurters with accuracy of ±1%. For all types of casings – natural or synthetic

Dosing tube for dosing device:

Standard Ø 12 mm; as an option possible Ø 10 mm, Ø 17 mm

Portioning device

In addition to perfect filling of meat products and other food products, the PSS SFV 720 Vacuum Filler can be also used for finalization of portions of minced meat.

For the PSS SFV 720 we offer as an option the Portioning Device PD 240 and also Forming Head FM 220. Thanks to these two additional equipment we can deliver a configuration of meat processing machines that will help you to produce an accurate portions of minced meat at the end of your production line.

Thanks to the gentle handling of the processed raw material throughout the processing cycle, the final portions have a homogeneous structure and also an aesthetically pleasing consistency.

Please your customers with quality processed and portioned minced meat.

Portioning device PD 240

The Portioning Device PSS PD 240 is an efficient device for dividing a line of minced meat into very accurate portions. As needed, the size of the portion and their number are set by the operator on touch screen control panel. Portioning device PD 240 can be used for portioning any type of minced meat (beef, pork, poultry, mixed…).

Forming Head FM 220

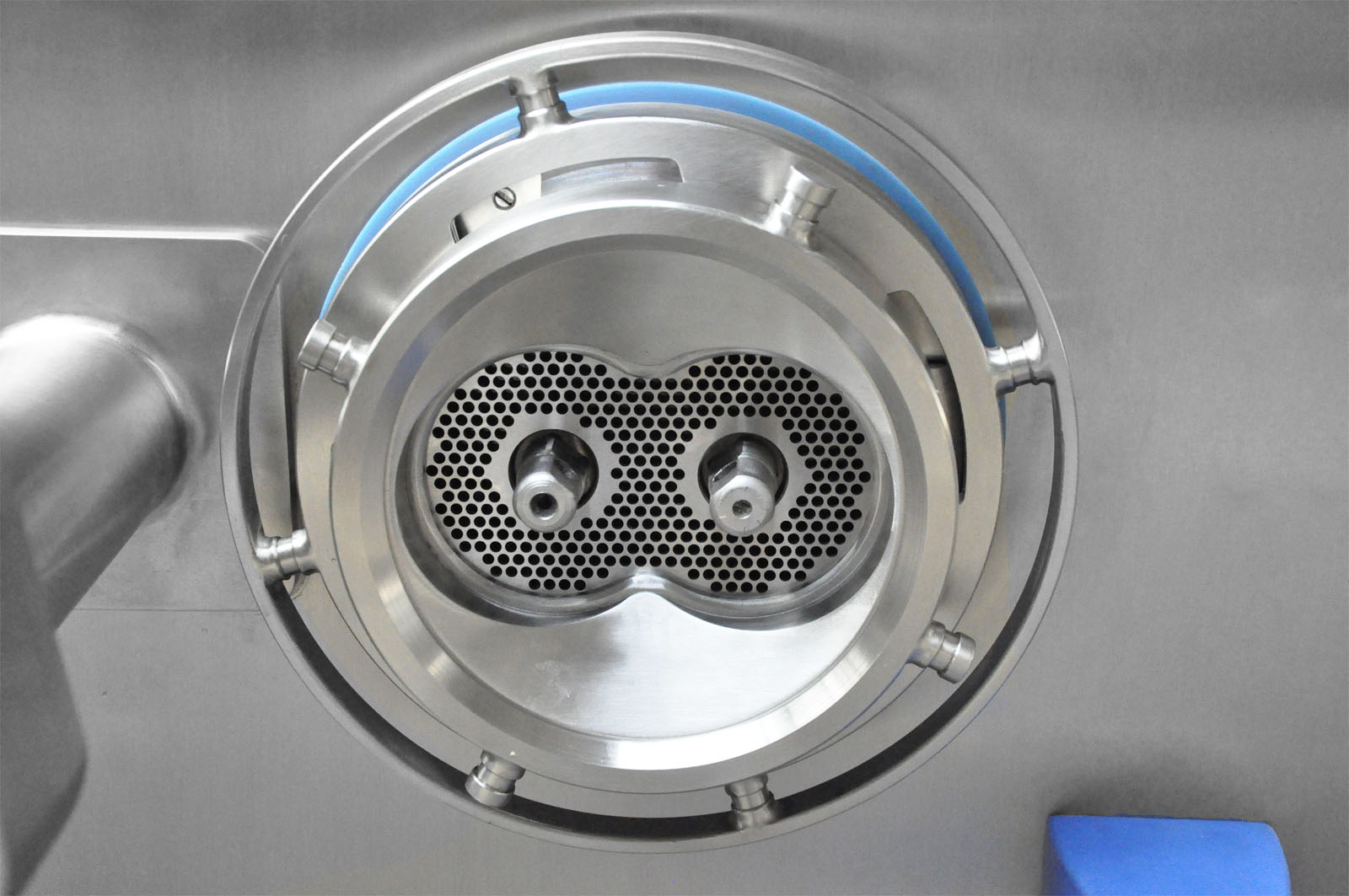

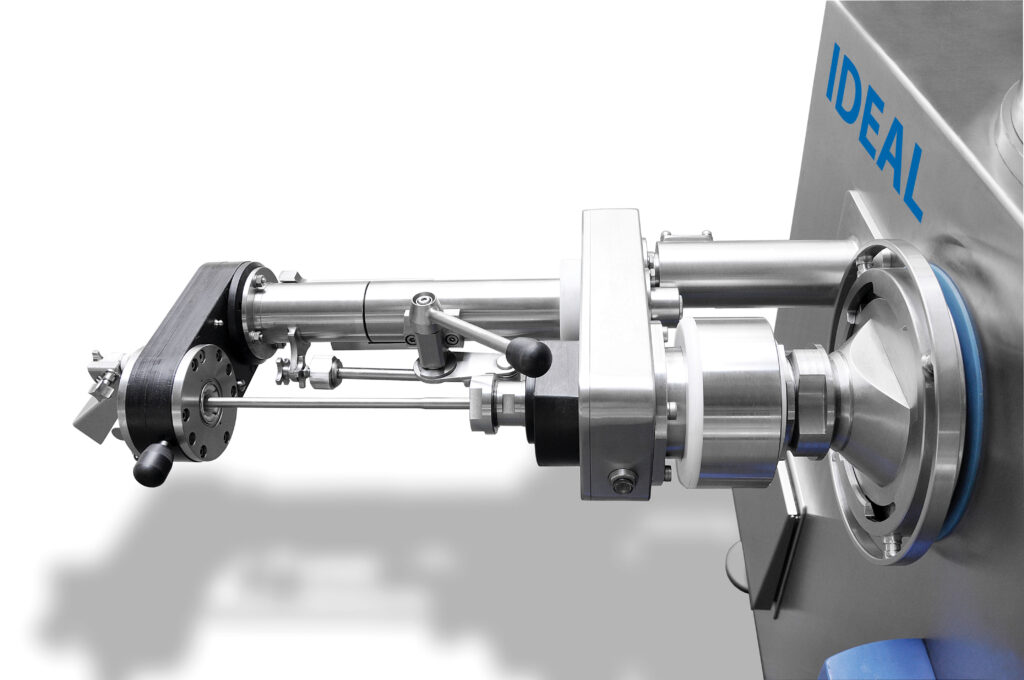

Grinding head

Grinding head (Grinder) with standard (Ø3,0; Ø5,0; Ø10,0 mm) or special (Ø2,5; Ø3,5; Ø4,0 ; Ø4,5; Ø6; Ø7; Ø8; Ø12; Ø16 mm) grinding plates complete (SFV 720)

Worms and plates for grinding of chilled and frozen pieces of meat (min. from -4°C) and for dosing – for the work in a clipping machine mode (SFV 720)

Worms and plates for grinding of chilled pieces of meat (at the temperature min. +1°C) up to 3kg – for the work in grinder mode with discharging of raw material into the trolley (SFV 720)

Hanging device

For an automatic linking line you will need our Speed Filler Vacuum SFV 720 or SFV 705 and as an additional device CS 75 Calibration System and HM 205 Hanging machine.

CS 75 Calibration System

– Capacity: max. 360 sausages/min (minimal weight of batch 35g)

– Dose length range 50 – 300 mm

– For synthetic casings with diameter from 22 to 40 mm (polyamid, cellulose, colagen)

– Servo drive 1,5 kW, 400 V, 50 Hz

– Connection to all PSS SFV Speed Fillers Vacuum

HM 205 Hanging Machine

– Capacity: max. 360 sausages/min (minimal weight of batch 35g)

– Dose length range 50 – 300 mm

– For synthetic casings with diameter from 22 to 40 mm (polyamid, cellulose, colagen)

– Servo drive 1 kW, 400 V, 50 Hz

– Connection to all PSS SFV Speed Fillers Vacuum